Welcome to Global Engineering Company!

Call us 9:00am - 6:00pm

+91 99444 90530

Monday to Saturday

9:00am - 6:00pm

E-mail us

info@globalengineering.in

About Us

Company Overview

Why Global

Processing and Facilities

Global Engineering

ENGINEERING is an Indian based organization providing complete solution for foundry Wood Pattern and Metal Pattern development. Global Engineering was established in year 2015 by Mr.Pramod Kumar and Mr.S.K.Senthil Kumar, who has over 22 years of experience in the field of Pattern making, Steel Methoding, Foundry technologies and Machining. We are a technology oriented Manufacturer and service provider, Our aim is to develop products and services to the World Class Quality.

why Global

Our main objective is to offer a one stop solution for our customers by providing innovative solutions, quality products and excellent service, the complete manufacturing solution.

We offer a wide range of additional services and, through a friendly and highly experienced team, the company is well positioned to provide its customers with a high quality product at the most competitive price. We pride ourselves with an excellent on-time delivery performance and also offer stocking facilities on-site; all part of the total solutions package offered by the GLOBAL ENGINEERING

At GLOBAL ENGINEERING, we pair tradition with innovation, enabling us to deliver quality machining to our local and global customers efficiently and effectively. Our processes are underpinned by our expertise and experience, as demonstrated through our bespoke 360 degree manufacturing process. From design to delivery.

GLOBAL have the capabilities to tailor machining to your requirements, whether this is a small, high value run or a bulk mainstream run. Please take a tour through our website to see what we can offer and why you should come to GLOBAL ENGINEERING for all your requirements. Our excellent team would be happy to discuss your project with you and provide a competitive quotation

In-House Design Facility:

Our in house design facility means that we eliminate the additional cost of having to deal with a third party design house. It also gives us the added comfort of complete control over the quality and integrity of the design stage.

In-House Tooling:

The production of tooling's & machining in-house is a fundamental component of our end-to-end service and allows for speedy and smooth changes with corresponding reductions in time and cost. Our in-house tool room is equipped with the most up to date software and CNC machinery.

In-House Service:

We offer a complete in-house end-to-end service incorporating design, tooling, rapid prototyping, casting and machining. This enables us to have complete control throughout the manufacturing processes.

One Stop Service:

We provide customers with an end to end one stop service cutting down on time scales and providing full trace ability throughout the manufacturing process

Processing

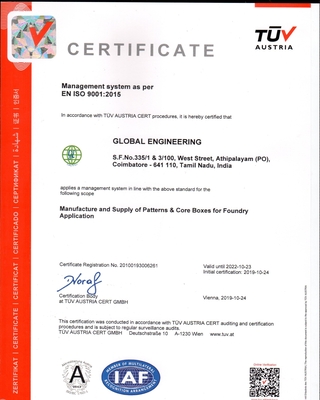

GLOBAL experienced workforce is guided by process oriented approach to execution in every part of the organization. This process oriented approach has allowed us to adopt a holistic approach to managing precision. Our pursuit of process driven precision starts with ISO 9001-2015 certified and compliant processes right from contract review to all the areas including risk management, project management, continuous improvement. We have adopted a process approach when developing, implementing and improving the effectiveness of our management system. We utilize the application of knowledge, skills, tools, techniques and systems to manage and improve our processes with the goal of exceeding your expectations. We continuously assess health and safety risks and implements controls and systems to reduce the risk.

We offer a complete in-house end-to-end service that enables us to have complete quality control throughout the design stage and manufacturing processes. We incorporate our own in-house design and tooling facility, rapid prototyping, machining and finishing. We use the very latest manufacturing techniques monitored for excellence at every stage. Precision machining and manufacturing services are provided by GLOBAL ENGINEERING across engineering sectors from its factory in Coimbatore, India.

Processing

-

♠

"ISO 9001-2015 certified"

♠ "Quality level of 99.99%"

♠ "Wide-ranging customer base"

♠ "Prototype, batch and volume production"

♠ "20+ experienced labour’s are working in our concern"

♠ "20+ experienced labour’s are working in our concern"

♠ "We provide inspection reports on every pattern development"

♠ "We had licensed solid works software for 3D Designing"

♠ "We have own in-house units for pattern making & machining"

♠ "We possess passionate management, and a highly skilled work force, which has been developed to fuel the growth of our business."

♠ "Good conditioned machines like vertical machining centre (VMC) with 3th axis, 3000 x 2000 x 800 CNC Router machine."

History of Global Engineering

-

2015

Established as a small Pattern Shop With 1500sq.feet Work Land.

-

2016

The moment when you learn to look for a new customer and stay in the community.

-

2017

Enlarged the Work Land up to 3000 Sq.feet area with 50 HP Power Support.

-

2018

Added new facility of (VMC) Vertical Machining Center with 3 Axis, in the size range of 1200mm x 600mm.

-

2019

Got ISO 9001 –2015 Certification.

-

2020

Enlarged the Work Land up to 5000 Sq. feet area.

-

2021

Established In-House Design Facility with help of SolidWorks Cloud Software.

-

2022

Added new facility of CNC Router Machine with 3 Axis, in the size range of 3000mm x 2000mm x 800mm height for larger size pattern machining.

Get in Touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91 99444 90530

Email us

info@globalengineering.in